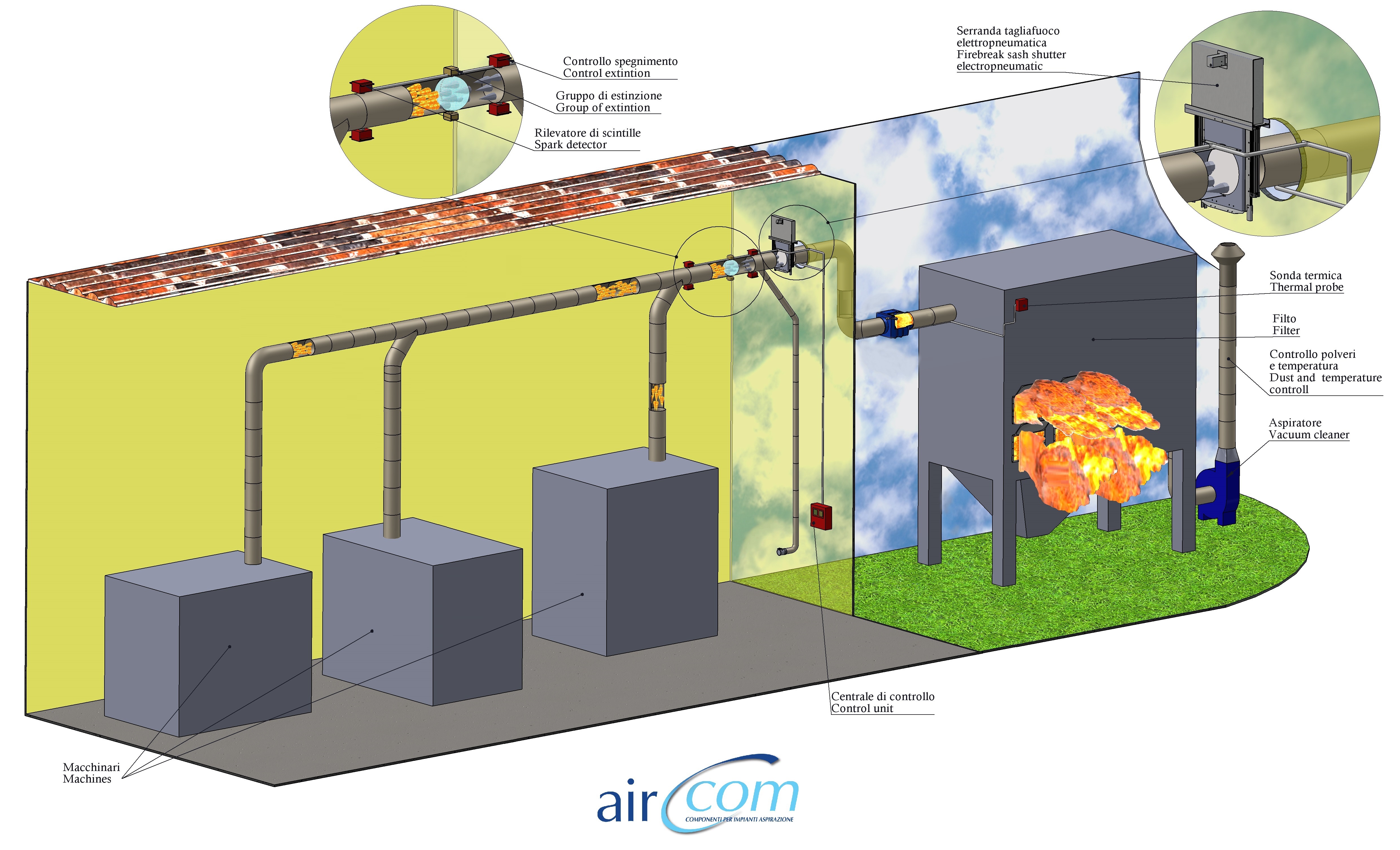

It is a question that production companies often ask us and that requires a timely answer to solve the fire problem, it is increasingly present in production systems.

AIRCOM SRL has investigated the causes of triggering , assessed the risks and found which type of shutter to install.

The fire can develop for various reasons in the Suction System:

- It can be caused by the machining tools in production machines;

- It can be caused by sparks arriving in the filter or silo;

- It can be caused by overheating of the material in the silo;

- It can be caused by natural events such as lightning or other;

- It can be caused by electrical systems connected to the vacuum system.

HOW CAN WE OPTIMIZE A FIRE PROTECTION SYSTEM?

Analyzing the causes of fire, it is important to block the ignition before it can cause the fire.

The answer to points 1 – 2 – 5 can be:

- Insert a spark or flame passage control system in the pipeline;

- Install a SHUTTER or FIREBREAK VALVE a valle (generally located in the wall of the building) with closing controlled by the spark or flame detector.

These options eliminate the possibility that sparks or fire, generated in the production system, reach the filter or silos.

The answer to points 3 – 4 requires two levels of protection:

- Protection from the spread of fire to the work environment by placing a fire damper outside the building (in the event that the harmful event starts from the silos) ;

- Extinguishing the fire in the silos with fire extinguishing systems installed in the silos.

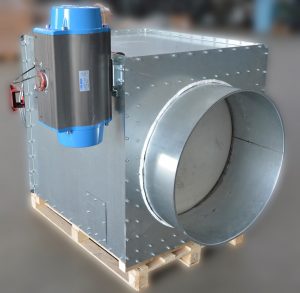

WHICH TYPE OF FIREBREAK SASH SHUTTER TO INSTALL?

It is very important to evaluate the type of protection to be installed based on the materials processed and the installation point , bearing in mind the basic points:

- When there is passage of material it is important that during the work phase the diaphragm is always completely outside the section of the pipe, otherwise in a short time the insulation wall is corroded by the passage material and is no longer fireproof ;

- It is important to know if the air flow is in DEPRESSION or PRESSURE ;

The Aircom Standard Guillotine model is recommended for DEPRESSION installation, while the AIRCOM FOLDAWAY model can be installed in PRESSURE ( or depression ); - The type of shutter closure is also important:

- the guillotine model with gravity closure ( MAX up to 750mm diameter), is equipped with a 72 ° C fuse which melts and closes when the heat passes. It means that the flame is stopped after its passage, it will not be able to continue because there will be no more passage of air upstream, it does not require a spark detector;

- with electro-pneumatic closure ( both guillotine and foldaway ) requires a signal from a spark detector placed upstream of the shutter (towards the operating machines) and closes instantly when the signal arrives before the spark arrives.

- ALWAYS AND ONLY INSTALL SHUTTERS CERTIFIED ACCORDING TO EUROPEAN STANDARDS;

- IT IS FUNDAMENTAL TO PUT SAFETY IN THE WORK AND IN GENERAL IT MUST BE IN 1st PLACE