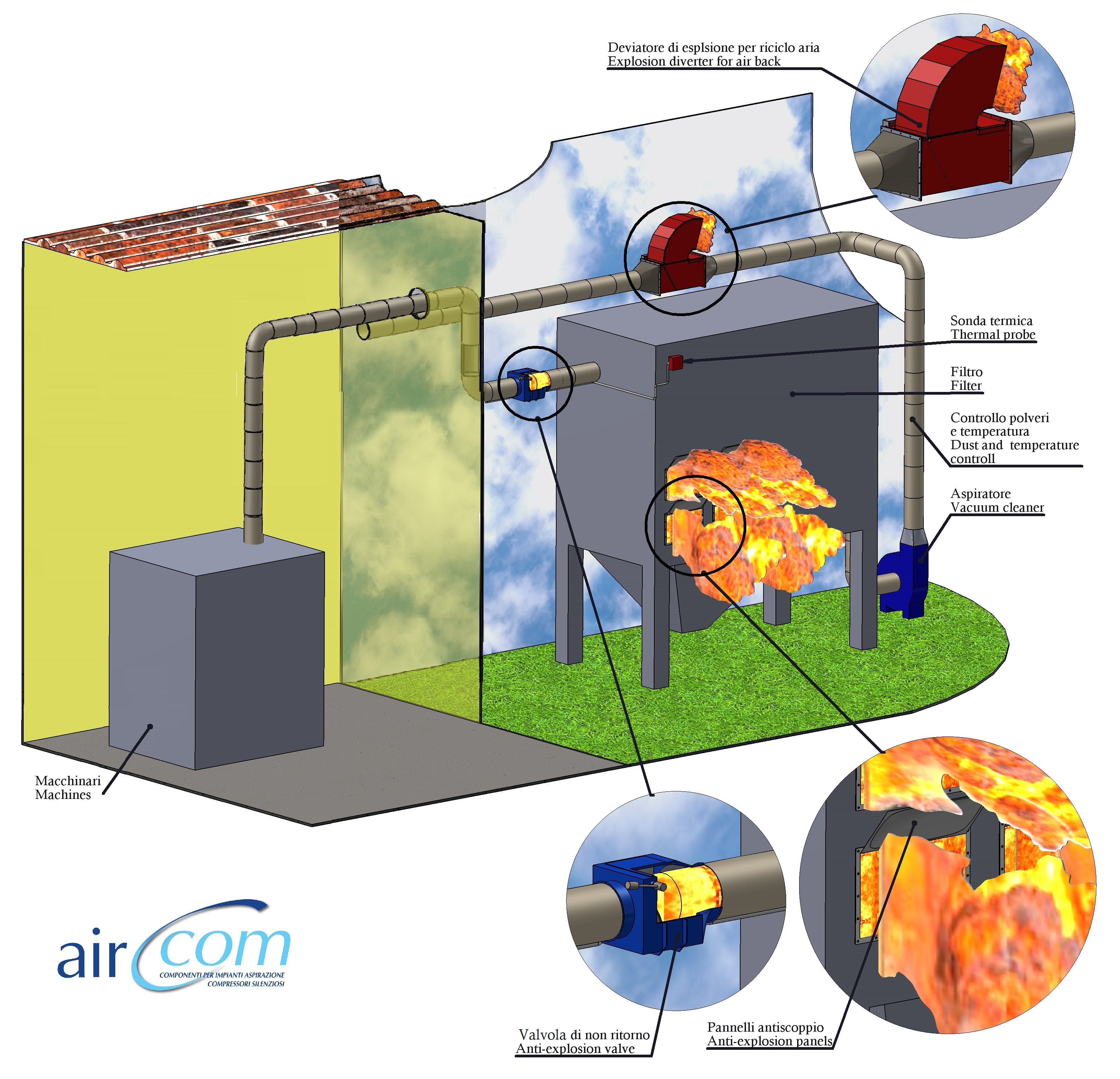

WHY AND HOW TO PROTECT THE BUILDING FROM DAMAGES CAUSED BY AN EXPLOSION

It is a very important question that the managers of a company ask themselves and ask us more and more often.

The first consideration to be made is to avoid damage to people in the workplace or nearby, then avoid damage to the company’s

facilities and equipment.

How to protect the work environment from possible outbreaks must be planned when a new production line is designed or

evaluated considering the processing activities already present in a company, taking into account the types of materials that

are in the production cycle.

Generally, the outbreak takes place in closed storage rooms of material derived from processing in the production system, which

can be silos, filters or other.

The explosion occurs after the overheating of the materials, which can be caused by a spark starting from the processing,

which triggers a combustion and slowly leads to an increase in pressure in the material storage room until it causes an explosion.

PREVENT, prevent sparks or incandescent material from reaching the deposit; The operation is possible by inserting a “control

system and blocking of sparks, fire or incandescent materials”.

Block the effect of the outbreak on the work environment. This operation is also very important for the safety of

people and things. This phase requires the insertion of a non-return valve – certified according to EN 16447 and EN 15089 standards –

which instantly blocks the propagation of the burst pressure in the pipeline towards the work environment, without any

external command.

Protect the silos or filter with explosion-proof rupture panels – certified according to the EN 14797 standard – which

open at the moment of the outbreak thus avoiding the deflagration of the silos or filter and the consequent damage that would

ensue.

Block the effect of the explosion in the air return duct in the work environment designed for the energy

recovery of the air (generally hot) in the work environment: by installing an explosion diverter in the duct, such as

Devex by Aircom.

SONLY WITH THE INSTALLATION OF COMPONENTS CERTIFIED IN ACCORDANCE WITH ATEX SAFETY RULES IT WILL BE POSSIBLE

TO PREVENT AND AVOID AS MUCH DAMAGE AS POSSIBLE IN THE WORKING ENVIRONMENT TO PEOPLE AND THINGS.